From Mist to Medals

Just over an hour by train from Shinjuku, the Godo area of Isehara, Kanagawa Prefecture, lives up to its name, which means “gate of the gods.” The mists rising from nearby Sagami Bay often shroud the peak in mysterious clouds, leading to the nickname Afuri-yama (Mount Rainfall). And tucked away in the lush foothills is Kikkawa Jozo, a century-old sake brewery that is gaining international acclaim.

Kikkawa Brewery is innovating its way to international gold

Mount Oyama, part of the Tanzawa Mountains, is one of Japan’s most sacred mountains. And tucked away in its lush foothills is Kikkawa Jozo, a century-old sake brewery that is gaining international acclaim.

Just over an hour by train from Shinjuku, the Godo area of Isehara, Kanagawa Prefecture, lives up to its name, which means “gate of the gods.” The mists rising from nearby Sagami Bay often shroud the peak in mysterious clouds, leading to the nickname Afuri-yama (Mount Rainfall).

Abundant rain filters through the rock and becomes the groundwater from which Kikkawa draws to make its sake and instill it with a rich flavor and full aroma.

For six generations, the Kikkawa family has worked its magic. Since the founding of the brewery in 1912, a long line of artisans has been combining the area’s clear water and top-quality rice to create their sake, Kikuyu.

However, in 2020, things were looking bleak. Facing bankruptcy and with no one to take over, it seemed that the sake brewery’s proud tradition was at an end.

Fortunately, the Shimada Group swept in, taking the brewery under its wing and providing a rather unusual kuramoto (brewery owner)—former architect Norimichi Goto—to lead the way. “I aimed for the sky by designing skyscrapers, but now, instead, I am diving into the deep ocean of sake-making traditions, which is very rewarding,” Goto said.

His first months on the job were not easy. “I walked into a rough situation. The brewery was on the brink of closing,” Goto recalls. “They hadn’t even ordered rice for the next season; that’s how dire things were.”

Left: Oyama Afuri Shrine (Photo: Kunihiko Meguro, Shinto Priest of Oyama Afuri Shrine)

Center: Kikkawa toji Masanori Mizuno • Right: Kikkawa Afuri sake

But he soon came to realize the strength of the brewery’s traditions and connections to the Isehara community. And he was impressed by how the toji (master brewer), Masanori Mizuno, and his team refused to abandon ship.

“I was so deeply touched that they stayed, and it is thanks to their hard work, and the support from the community and Oyama Afuri Shrine, that we got things running again so quickly,” Goto said.

While Kikkawa is still producing the locally beloved Kikuyu brand, with the change in leadership in spring of 2021 came a new brand, Afuri. Despite being new, the Afuri brews have already received gold medals at multiple world-class sake competitions. Nari, a refined junmai daiginjo, even won the Platinum Award at the prestigious Kura Master competition in 2022 in Paris.

“We want to push the boundaries of sake, creating new varieties and bringing our products to new markets, to share the culture of sake with as many people as possible,” Goto shared.

This includes combining traditional processes with innovations that allow the brewing process to be more sustainable, such as reducing waste by only polishing away 10 percent of the rice surface or switching from oil-powered steamers to more efficient electric ones.

For those interested in trying Kikkawa’s new generation of brews, why not sample Rosy-Kasumi, a low-alcohol sake (just eight percent) that is gaining attention for its beautiful, fresh flavor. The use of an unusual pink yeast gives several of the Afuri varieties, such as the floral ‘Ohana, a festive, rose-hued tinge. More expert sake drinkers will be enthralled by Terra/Y, another Kura Master gold medalist made using minimally polished rice and slowly aged at low temperatures for an elegantly sweet finish.

This is definitely a brewery to watch.

Learn more about Kikkawa:

www.kikkawa-jozo.com/en/

Sushi Singularity

Is this a glimpse of the future of food? Japanese scientists and companies are developing 3D food printers to produce sushi, *wagyu*, and a host of other foods. They say the technology holds great promise for personalizing food to meet nutritional needs, reducing food waste, and even providing something to eat during extended space travel. “I think there’s huge potential. Food itself will probably change,” said Yamagata University’s Hidemitsu Furukawa.

3D printers offer a vision and taste of future food—but will consumers embrace it?

Listen to this story:

Is this a glimpse of the future of food? Japanese scientists and companies are developing 3D food printers to produce sushi, wagyu, and a host of other foods. They say the technology holds great promise for personalizing food to meet nutritional needs, reducing food waste, and even providing something to eat during extended space travel. “I think there’s huge potential. Food itself will probably change,” said Yamagata University’s Hidemitsu Furukawa.

The soft and wet materials-engineering scientist is developing a 3D food printer dubbed the Laser Cook that heats and hardens liquid food poured into a mold. He envisions the equipment being used in convenience stores within the next 10 years to prepare custom-designed food for consumers. He is even in initial discussions with Seven & i Holdings Co. Ltd., the owner of the 7-Eleven chain, about doing just that.

As Japan’s population ages, the technology could also prove useful for feeding elderly people with specific nutritional needs or providing softer food for those who have trouble chewing and swallowing, Furukawa and other developers have noted.

The sushi and wagyu projects are still works in progress, and there are obvious questions about how receptive consumers will be to food that may seem industrial or artificially engineered. But already, 3D food printers are being used at universities, restaurants, and food companies in Japan and around the world. Developers predict they will become fixtures in household kitchens within a generation.

“We’re trying to create a competitive food culture for the 21st century,” observed Ryosuke Sakaki, who founded Open Meals, a venture backed by ad agency Dentsu Inc., which is pursuing seven projects that involve 3D food printers, including some that essentially squeeze sushi and wagashi (Japanese confections) out a nozzle.

Sakaki remarked that getting the taste and texture right have been huge challenges, and he has enlisted the help of sushi chefs in this regard. But he acknowledges that the results will never measure up to the sushi we are used to. “We’ll never be able to match that,” he admitted, adding that the fish or seafood portion of printed sushi may be crispier and may be placed on top of regular pats of rice shaped by a machine. “We’ll need to think of it as a new kind of sushi experience,” he concluded.

Still, Sakaki has high hopes. By year-end, Open Meals plans to hold an event at which printed sushi and wagashi can be eaten and the technology demonstrated. If it is well received, he hopes to open a restaurant serving the food in the not-too-distant future. The name? Sushi Singularity.

Mini Food Factories

These Japanese ventures aim to join a number of startups from Europe, the United States, and China that have taken the lead in this nascent business.

Food printers, which emerged 10–12 years ago, work in a variety of ways. The dispensing function operates like that of 3D printers with which we may be most accustomed. But, whereas the latter create plastic shapes, the function here causes capsules of paste-like or liquid food to be squeezed through a nozzle to produce a three-dimensional shape that can be eaten or baked. The method lends itself to creating cookies, cakes, chocolates, and other confection. Some dessert shops have already started to display them.

But many machines can also handle mashed vegetables and even minced meat. The Foodini, a 3D food printer designed by Barcelona-based Natural Machines, comes equipped with capsules that users can fill with almost any sort of food, as long as it’s relatively soft.

The technology is not as foreign or far-out as it might sound, Chief Executive Officer Emilio Sepulveda told The ACCJ Journal. And it is already widely used in food processing plants. “These printers use the same processes and same technology that major food brands use to create pasta or meat patties,” he explained. “It’s basically 3D printing, but no one calls it that.”

Tackling Food Waste

The Laser Cook printer being developed by Yamagata University’s Furukawa operates differently. It combines water with dehydrated, powdered food, which is poured into a vessel and then zapped with a laser to cook or harden it.

In this way, 3D printers can help reduce food waste, Furukawa and others have said. Instead of discarding food that isn’t sold at the supermarket—or the “ugly” vegetables that don’t even get to the store, because they’re not the ideal shape—it can be turned into powder and saved for future use. “If we think differently … and convert food into powder, it becomes an on-demand item and there’s little waste,” Furukawa explained.

There’s also potential here for use in space, he added. Transporting lightweight powder is easy. It doesn’t require refrigeration and it can last several years. “So, when we go to Mars—a journey that could take two or three years—this kind of food could be used. You can make it just by adding water.”

The technology is something the Japanese government is getting behind as well. One goal of the Cabinet Office’s Moonshot Program is to reduce food waste, and some developers, including Furukawa, are receiving government research funding.

Personalized Nutrition

Another benefit, scientists and developers say, is that ingredients can be customized to meet individual nutritional needs. That might include vitamins and other supplements.

It could be particularly helpful, in Japan and other developed nations, for the growing ranks of elderly people, who may not get enough nutrition as their stomachs and appetites shrink. Producing softer food can also help elderly people who have dysphagia, or difficulty swallowing, a common problem for those with Parkinson’s disease. “With this technology, you can make dense nutrition,” Furukawa explained.

Athletes and soldiers could also benefit from specially designed food. Perhaps during disasters, the technology could also be used to feed people who lack provisions, developers say.

“The opportunity and potential to use this in hospital settings, in homes for the elderly, where consumers need very specific nutrients, and where nutrients must be provided at specific times—that’s a huge market,” said Jennifer Perez, a venture capitalist at the $20 million Future Food Fund, established by online food delivery service Oisix ra daichi Inc., which invests in food-technology ventures.

So far, the fund hasn’t invested in any 3D food printing companies, but Perez sees great potential. “This technology is a dream of the future, but it’s starting to happen right now,” she added.

Synthetic Wagyu

Japan is on the cutting edge in one particular area: developing “structured” synthetic meat that contains ripples of fat, blood, and sinew, just like the steaks we might buy at the supermarket.

While food printers have been able to process fresh and synthetic ground meat for some time, Osaka University bioengineer Michiya Matsusaki is spearheading research and working with Shimadzu Corporation to develop chunks of synthetic, or cultured, wagyu, Japan’s famous marbled beef.

The complicated process involves injecting stem cells from fresh meat into a gelatinous bath. The cells are then exposed to stimulating chemicals to differentiate them. Some become tiny muscle fibers just 500-microns wide, while others become tissue, such as fat and blood vessels.

The muscle fibers are then assembled to create tiny pieces of meat—72 strands, for example, create a tidbit just 5 millimeters x 5 millimeters x 1.5 centimeters. Matsusaki has not been able to do a taste test yet, because he hasn’t received clearance from the university’s ethics committee. But his team aims to complete the project for demonstration at World Expo 2025 in Osaka, where they hope to offer visitors tiny edible pieces of such printed wagyu.

Matsusaki said he’s received inquiries about his research from a number of companies around the world. “We’re getting lots of interest from Singapore, Dubai, and the United States,” he shared. “Companies that make synthetic meat don’t have the technique to make this shape.”

Key reasons for the project include concern about the environment and the possibility that the world will face a shortage of meat in the future, making it difficult to feed the growing population, Matsusaki explained. Increasing the number of cattle—and expanding grazing land to meet their needs—would lead to the destruction of more forests. And cows produce a lot of methane, a potent greenhouse gas.

The equipment being developed with Shimadzu would allow consumers to manipulate the percentage of fat they want in their meat. “If you had one of these machines in your home, you could decide on the fat content and shape you wanted,” he observed. “Press a button and it would be done the next day. That’s the kind of future we’re trying to create.”

Very Analog

But how does such food taste, and will consumers go for it? Japanese are quite open-minded about robots and other applications of technology, but when it comes to food they have very high standards for quality, texture, taste, and freshness.

Tetsuya Nojiri, CEO of Oishii kenko Inc.—creator of the app that goes by the same name and who is not involved in 3D printer development—said he can see some positives in the technology, particularly for addressing nutritional needs of the elderly. However, he believes it won’t appeal to most Japanese consumers, and that it would take many years to be accepted. “Most people want food that is natural, safe, and tasty,” he stated. “That’s very analog, not digital.”

Aiming to contribute to health and healthcare issues through dietary management is the Oishii kenko app, which won the Empowering Patients Award and People’s Choice Award at last year’s American Chamber of Commerce in Japan Healthcare x Digital competition. The app’s name means “tasty health” and it provides recommendations for nutritionally balanced, delicious meals using artificial intelligence and Big Data.

Nojiri suggested that, if the equipment to make 3D printed foods is fun and easy to use, he can see some consumers using it to make niche products such as chocolates and other confections. He can also see it being put to work in larger-scale settings, such as hospitals and universities. “These printers have potential, but it’s hard to imagine that they would be used to prepare food for the ordinary person,” he added.

Perez of the Future Food Fund feels that more time and research is needed to gauge consumer receptivity. “Consumers are curious but, ultimately, it comes down to: Is the product going to taste good?”

Taste and texture are indeed very difficult, if not impossible, to replicate on a food printer. Chocolate and baked goods are easier on that score, but synthetic meat—or hybrid meat mixed with soy or other plant products—has generally proved disappointing. “It doesn’t really taste like meat yet, so that’s a problem,” Matsusaki remarked.

Price, Speed, Scalability

The 3D printers currently being used have built-in limitations on what they can produce, Sakaki explained. “Food made with certain ingredients will harden and taste good, but [made with] others will not. There are also limitations on how you can design the food to come out. And it takes quite a while to make each piece, so that raises the price.”

Yes, as with any new technology, price is an issue. Natural Machines’ Foodini sells for about ¥800,000 at current exchange rates ($6,000), although the company also offers less expensive subscription plans for set periods of time. The Laser Cook being developed by Furukawa costs roughly ¥1 million (about $7,500). Other machines being developed in Japan, such as the wagyu and sushi printers, do not yet have price tags.

Speed and scalability are other problems, according to Perez. Printing a simple round cake can take seven to 15 minutes, and making just one more complex structure can take 45 minutes to an hour. “When you compare that to what you can do on the standard factory line, it doesn’t make a lot of sense,” she said. “When you look at the logistics, it doesn’t quite work yet.”

On the flip side, once you have a successful product, it’s highly reproducible, Perez pointed out. And that data could be shared with other machines to create the same product on another continent—or in outer space.

Suraj Gujar, principal analyst for disruptive technologies at Meticulous Research in Pune, India, sees 3D printers as remaining a relatively niche product used by bakeries, caterers, hotels, and restaurants—but not the wider public.

The equipment is far too expensive, hefty, and slow to catch on among ordinary consumers, at least for the foreseeable future, he offered. Also, most printers don’t have a cooking feature, so that involves another step, adding more time and work. And some can be tricky to operate, he added.

“The consumer has to be tech savvy, because if you want to print food, it means you have to give a command to a machine. And if you want a customized design, then you have to program that into the computer,” Gujar explained. “If it’s for a cake, I would be happy to have it. But if it’s for daily food, I’m skeptical.”

To counter negative impressions that printers generate “plastic food,” Natural Machines’ Sepulveda said that, most often, fresh ingredients are used with the Foodini, several dozen of which are already being put to work in Japan at food companies, universities, hospitals and restaurants.

To win the trust of consumers in Japan, it’s important to work with established food brands, Sepulveda noted. Natural Machines is working with Hankyu and Dentsu. “Japanese corporates are super open and looking for partnerships that can bring them this extra value that they have not been able to develop on their own,” he added.

And demand in the region is on the rise: Asia has overtaken North America as the Foodini’s top market.

Despite the obstacles, developers say growing consumer awareness and concern about environmental, health, and sustainability issues are making them more receptive to this new technology. “Sustainability is getting more attention,” said Open Meals’s Sakaki, “including concerns about fish catch and resource use. 3D printing is one way to address that, so I think people will be receptive.”

Ramen Romance

Chinese noodles first gained popularity in Japan in 1859, when centuries of isolation ended and the port of Yokohama opened for international trade. Yokohama, a short jaunt south from Tokyo, prides itself on serving some of the country’s best ramen, and has two museums to celebrate the cheap, delicious, and filling meal.

A flavorful world of history and innovation awaits you in Yokohama

Listen to this story:

Chinese noodles first gained popularity in Japan in 1859, when centuries of isolation ended and the port of Yokohama opened for international trade. At the same time, a nationwide ban on eating meat was lifted, bringing to the table new flavors. To a bowl of basic Chinese-style noodles, Japanese chefs added a slice of fatty chashu (braised pork belly) and unique soup stocks made with local ingredients, such as miso, kelp, bonito, and clams. And in doing so, they created a delicious umami-rich dish now famous the world over: ramen.

The Raumen Museum

Yokohama, a short jaunt south from Tokyo, prides itself on serving some of the country’s best ramen, and has two museums to celebrate the cheap, delicious, and filling meal. Minutes from Shin-Yokohama Station, the Raumen Museum (the unique spelling reflects the way the word used to be pronounced) is a great place to start your ramen reconnaissance. This food-themed amusement park opened in 1994, the brainchild of industrialist Yoji Iwaoka, who envisioned a truly distinctive museum.

It’s ¥380 to enter the museum which, despite benches shaped like ramen ingredients and a carpet decorated with narutomaki fish cake, looks at first fairly ordinary. There are displays in English and Japanese that chart the history of ramen, and several impressive exhibits that reflect regional specialties. There are even several walls of various donburi (pottery bowls) used throughout Japan. Of special charm is a reconstruction of Rairaiken, the shop that set off Japan’s first ramen boom after it opened in Asakusa in 1910. With the help of 13 Chinese cooks from Yokohama’s Nankinmachi, Rairaiken is said to have ladled out between 2,500 and 3,000 bowls of ramen a day. The first floor also has a nifty gift shop, with a wide variety of ramen-related goods, such as heat-n-serve packs, recipe books, ramen bowls, and even a curious treat called ramen chocopuffs.

What really sets the Raumen Museum apart, though, is found in the second basement. Stepping into this vast two-story section of the museum is like discovering a time portal; though you know you are inside a building, you would swear you are outside at dusk, walking the backstreets of a bygone era. A huge central court, lit by cinema posters, neon pachinko signs, and light bulbs strung from second floor living quarters, also holds half a dozen actual ramen restaurants doing brisk business. Before queuing there, though, be sure to tour the backstreets of the town, all along the periphery of the food court. You’ll find the alleyways more intricately detailed than movie sets. The humble wooden homes, speakeasies, candy store, tobacco shop, police box, and even a phone booth add up to a realistic scene you’ll swear you’ve actually been to, somewhere in Shitamachi. Attention to detail—a chalked hopscotch, children’s yukata hung out to dry, and a public bath entrance (that’s actually an elevator)—evoke an era when lives were more intimately connected, and community coalesced around a simple bowl of noodles with family and friends.

Museum founder Iwaoka’s son, Takuji explains that his father wanted to recreate a 1958 retro townscape, not just for nostalgia but also because that year marked the invention of instant noodles by Momofuku Ando, a true turning point for the internationalization of ramen.

Heading into the central square, snag tickets from a vending machine for the ramen of your choice. The shops and selections come from around Japan and change occasionally, but the important point is that you can choose regular or “mini portion” servings, which allow you to sample several of the shops’ offerings.

You might see homemade slabs of pork hanging here and there, but vegetarian ramen options are also always on offer (try Komurasaki, from Kumamoto). The variety of soups—usually in soy, miso, or salt seasonings and bases of pork bone, fish, chicken, or vegetable broth—make for infinite combinations. The museum is a great place to develop your vocabulary and taste for ramen, and the atmospheric setting might make you yearn for the good old days of Japan.

The Cup Noodles Museum Yokohama

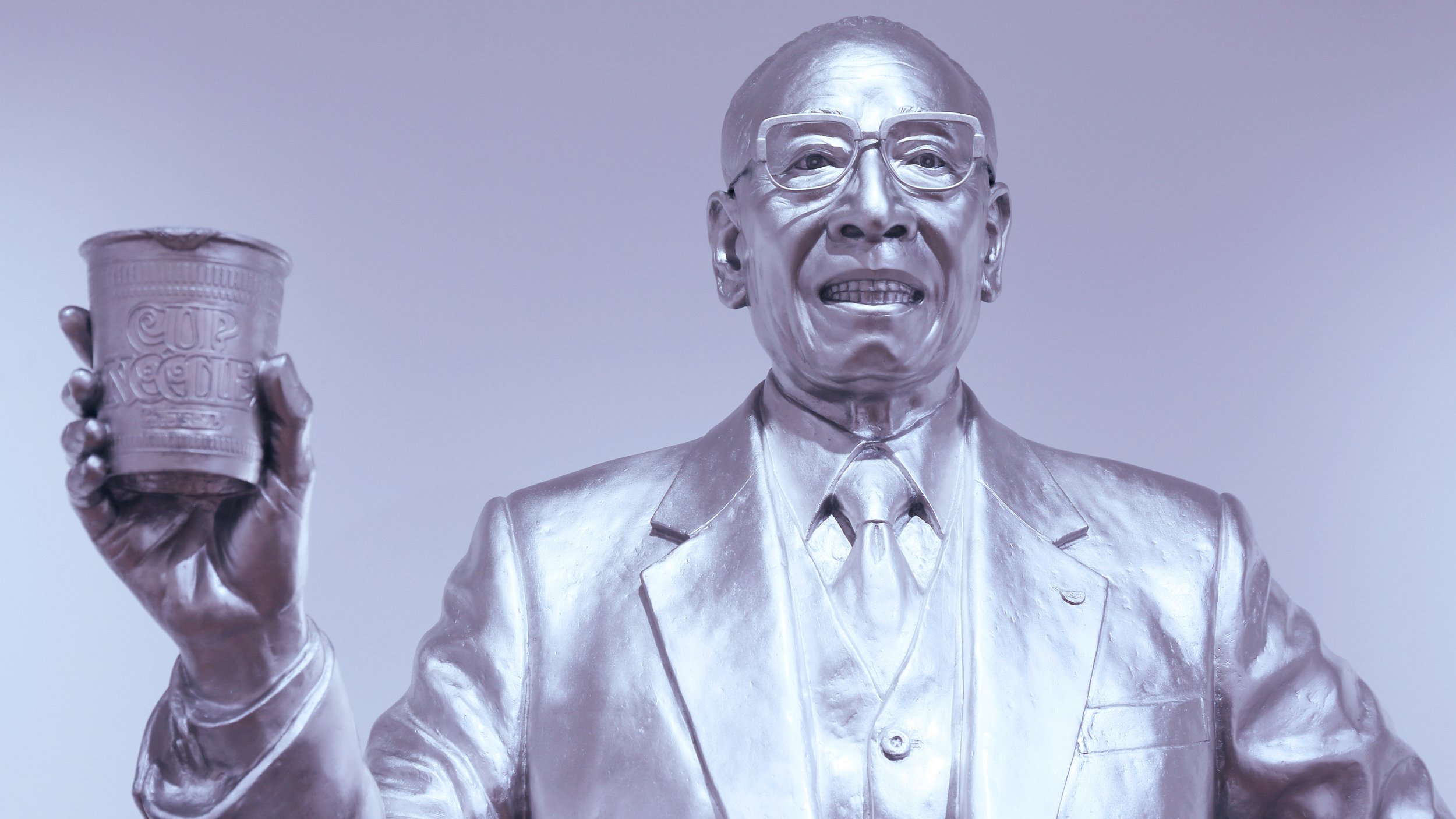

The year immortalized by the Raumen Museum’s fantasy backstreets, 1958, is the same one in which Momofuku Ando realized his dream of making instant ramen noodles. The whole story behind Ando’s development of instant ramen is packaged beautifully at the Cup Noodles Museum, a 12-minute walk from Sakuragicho Station on the JR Yokohama Line.

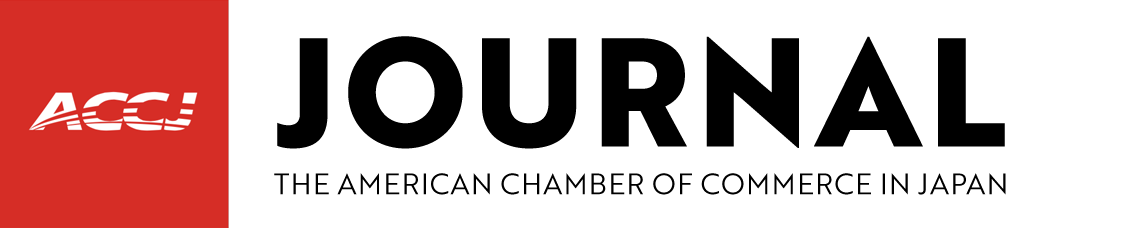

The minimalistic red brick exterior of the facility, officially known as the Momofuku Ando Memorial Museum, was conceptualized by Creative Director Kashiwa Sato to express “simplicity devoid of the unnecessary” and to stimulate creative thinking. The vast clean entryway features a 24-meter-high back wall that extends up all five floors of the museum, and a white nebuta-style float made of washi paper in the shape of Nissin’s popular product.

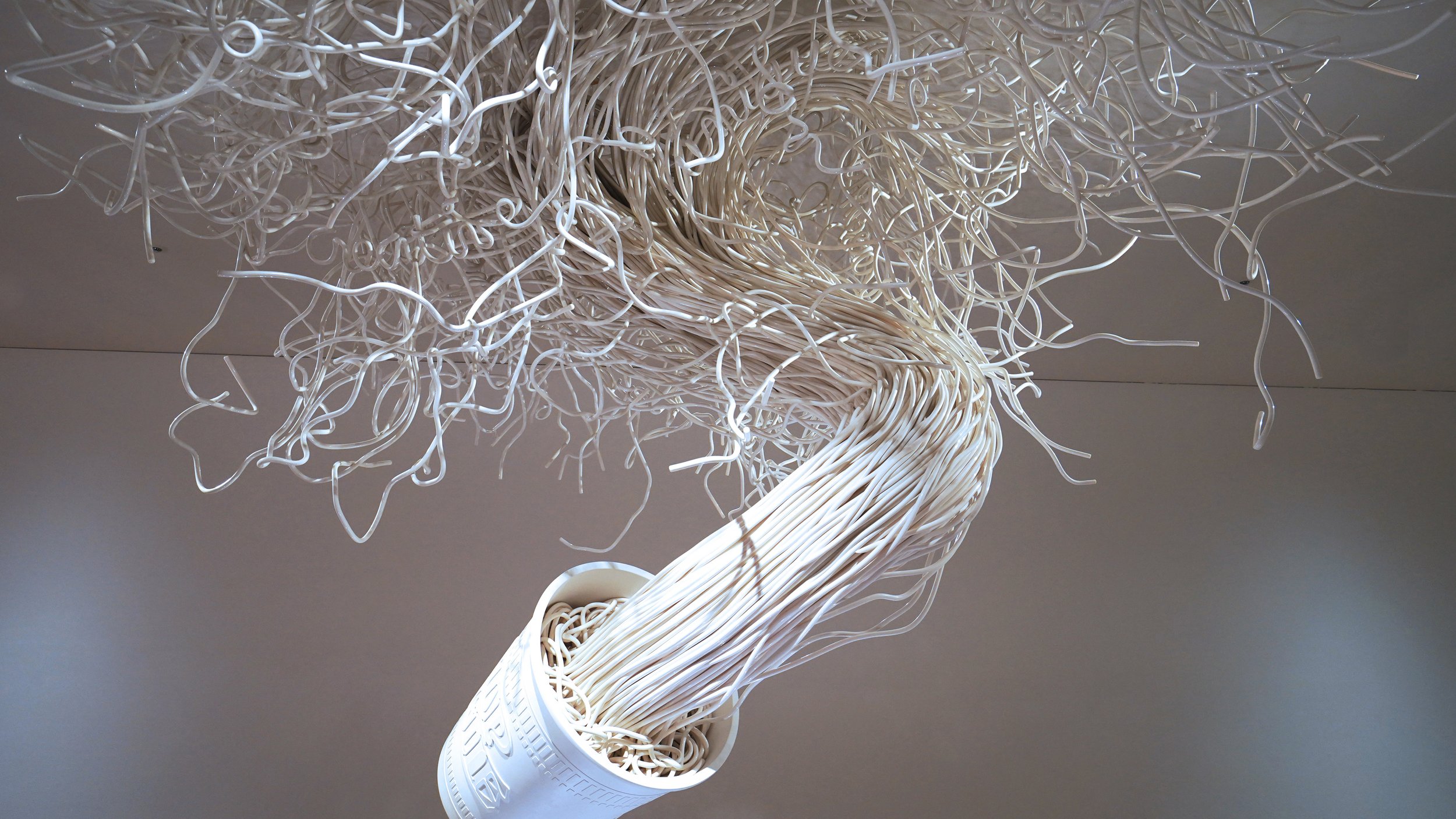

Corporate Communications Division Manager Kazuki Tsurumaru notes that the facility “really looks like an art museum”—an impression borne out by displays on the second floor. One entire room, the Instant Noodles History Cube, has a floor-to-ceiling exhibit of every variety of fast-food noodles, from Ando’s very first pack of Chicken Ramen to the items currently on sale. There are also cup versions, some of which include flavor variations sold in other countries. Tsurumaru points out that the early packets of Chicken Ramen had little windows, “so people could see what was inside, because they didn’t know.” They sure know now.

The next exhibit, Momofuku’s Work Shed, is a faithful recreation of the place in which Ando struggled for a year to create his invention. Tsurumaru reveals that it was Ando’s wife who provided the catalyst for his breakthrough. “Ando watched her cooking tempura and realized that, when the noodles were fried in oil, the moisture was forced out, making it possible to preserve them for a long time. He also discovered that hot water poured over the noodles was absorbed through tiny cavities formed during dehydration. The water seeped into the noodles, restoring them to their original soft state.

The message here is that inspiration for inventions can come from literally anywhere and that, even in humble surroundings, it’s possible to create something extraordinary.

Each of the exhibits on the second floor underlines Ando’s thought process. An oversize cup with white noodles spilling out, for example, has words hidden in the noodles themselves, encouraging viewers to look at things carefully and from all angles. A nearby separate room helps children learn how great ideas can arise from simple tools, and that by using your noodle, so to speak, you can come up with unique inventions by understanding the needs of others.

The third floor offers two hands-on experiences. One (reservations required, tickets ¥800) involves making Chicken Ramen by hand, starting with kneading, spreading, and steaming the wheat flour and then drying it with a flash-frying method. The other (¥400 tickets sold at the entrance) is a fun experience in which you design your own Cup Noodles, from illustrating the exterior of the cup itself to choosing the soup flavors and toppings. Children will love adding the likeness of Chicken Ramen’s mascot Hiyoko-chan, made from dried fish cake, to their concoction. Staff then seal the lid, shrink-wrap your creation, and place it in an “air package” that you pump into a nifty pillow to safely tote home.

To round out the fun, the fourth floor has a fabulous playground (check for current Covid-19 restrictions) where kids “become” noodles in a factory. Nearby, the Noodles Bazaar serves up noodle dishes from eight countries, from Kazakhstan to Italy. The highlight here might be an outrageously confusing, but delicious, ramen ice cream!

Ramen Trick

After two excellent museums, you might want to sink your chopsticks into the ramen made at one of Yokohama’s independent ramen shops. If that’s the case, Yokohama Convention and Visitors Bureau Management Planning Department Manager Shisei Aoki has a recommendation: Ramen Trick, located a minute from the Blue Line’s Yoshinocho Station, Exit 3. Despite the unsettling name and the informal atmosphere of the joint, decorated with bombastic rooster illustrations, the place is the real deal. Ramen Trick was opened in 2012 by Noboru Nishigaki and his wife, Kazumi. “Before opening,” Noboru recalls, “we were working in Chinatown, above the Trick Art museum, and one day, we realized the word ‘trick’ sounded like ‘tori-ku’ (eat chicken), so we chose the name.”

Puns aside, Ramen Trick is all about chicken—no other meat products are on offer—and if you visit between hours, be prepared to see big plastic pails of chicken parts being prepped for the stock pot bubbling away in the back of the kitchen. Three kinds of fowl, including Okayama’s Sansui, Nagoya’s Cochin, and Yamanashi’s Shingen simmer away with dried tomatoes and konbu (seaweed), bringing out unique umami notes. A quick glance at the walls reveals the restaurant has prizes—including a Bib Gourmand Award from Michelin—to back up Aoki’s recommendation.

By all means, try the tokusei (special) salt-broth ramen (¥1,200). In a light golden broth, the toppings include crisp fresh spring onions, chicken meatballs, chicken chashu, a sliver of red onion, both halves of a meltingly soft ajitsuke (marinated) egg. For the salt ramen dishes, the noodles, sourced from noodle-maker Mikawa Seimen, include a bit of bran to add to the flavor and texture. Guaranteed, after tasting this ramen, the main trick will be to resist ordering a second bowl on the spot.

Learn more …

The Raumen Museum: www.raumen.co.jp/english

The Cup Noodles Museum Yokohama: www.cupnoodles-museum.jp/en/yokohama/

Yokohama Convention & Visitors Bureau: www.yokohamajapan.com

Of Sake and Scythe Weasels

On November 4, 2021, an evening of culture, flavors, and learning took place at Kojima Sohonten Co., Ltd., Japan’s 13th-oldest sake brewery, established in 1597. Located in Yonezawa, Yamagata Prefecture, Kojima Sohonten is best known for its award-winning Toko sake. When you’re inside the brewery, the dedication and craftsmanship of more than 400 years of brewing seem to infuse the darkened wood of the huge barrels. On this day, however, amid the ongoing travel restrictions, it was innovation—along with multiple cameras—that helped bring the historical setting to travel writers on the east coast of the United States.

A surprising view of Tohoku with Alex Kerr and John Gauntner

Listen to this story:

On November 4, an evening of culture, flavors, and learning took place at Kojima Sohonten Co., Ltd., Japan’s 13th-oldest sake brewery, established in 1597. Located in Yonezawa, Yamagata Prefecture, Kojima Sohonten is best known for its award-winning Toko sake. When you’re inside the brewery, the dedication and craftsmanship of more than 400 years of brewing seem to infuse the darkened wood of the huge barrels. On this day, however, amid the ongoing travel restrictions, it was innovation—along with multiple cameras—that helped bring the historical setting to travel writers on the east coast of the United States.

Jarman International KK proposed the special webinar as a way to satisfy the wanderlust of frustrated Japan lovers overseas. We used our Covid-induced thinking time to bring together sake expert John Gauntner and author Alex Kerr to speak about what makes the Tohoku region so culturally distinct. The event was hosted by the Japan National Tourism Organization’s New York office and co-produced with JR East Marketing & Communications, Inc., known as JEKI.

Flavorful Culture

What better way to connect with viewers than to send delicious sake to each, along with recipes which perfectly match the various brews? Perhaps having Gauntner and Kerr intertwine the story of Tohoku with an engaging discussion about sake flavor profiles and bouquets?

The evening proved to be the perfect appetizer for the travel boom we expect will hit next spring. Gauntner taught participants how to properly heat and taste sake, suggested pairings for various cuisines, and vividly showed how the flavor profile of each bottle is deeply connected to the region, its rice, and the craftsmanship.

Lost Japan author Kerr brought to life the mystical side of Tohoku. Do you know what bait to use to catch a kappa (river sprite) in Iwate? Have you heard the chilling tale of the kamaitachi (scythe weasel)?

Travel Preview

Tohoku is also filled with beautiful hamlets, forgotten by time, and is home to some of the few remaining views of old Japan, such as the now-rare red pines and the last surviving garden of the Heian Period (794–1185). As people around the world connect with Tohoku through innovative online events, we expect more travelers to follow the lead of Dr. Edwin O. Reischauer, former US Ambassador to Japan, and venture to the “other side of the mountain.” Tohoku is the cradle of Japanese civilization, and is sure to wow any visitor with colorful festivals, thatched villages, folklore, and, of course, plenty of wonderful sake.